Introduction

In today’s fast-paced business environment, inventory management is more than just keeping track of stock—it’s about leveraging technology, data, and strategy to maintain a competitive edge. A robust business inventory program plays a pivotal role in ensuring that businesses can monitor, manage, and optimize their inventory effectively. From reducing holding costs to improving customer satisfaction, a well-implemented inventory program can be a game-changer for businesses of all sizes.

This comprehensive article will explore the concept of a business inventory program, its components, benefits, types, implementation strategies, challenges, and best practices to help enterprises navigate the complex landscape of inventory control.

1. What Is a Business Inventory Program?

A business inventory program is a software solution or system designed to help organizations manage the flow of goods, monitor stock levels, track orders, organize warehouse operations, and forecast future inventory needs. It automates and streamlines the entire inventory lifecycle, from procurement and storage to sales and delivery.

Key Objectives:

-

Maintain optimal stock levels

-

Prevent stockouts and overstocking

-

Reduce waste and shrinkage

-

Improve order accuracy and fulfillment speed

-

Provide real-time data and insights

2. The Importance of Inventory Management

Inventory is often one of the largest investments a business makes. Poor inventory management can lead to lost sales, customer dissatisfaction, cash flow issues, and storage problems. On the other hand, effective inventory management ensures:

-

Efficient use of capital

-

Seamless operations

-

Strong supplier relationships

-

Improved customer experiences

Especially in industries like retail, manufacturing, logistics, and e-commerce, inventory plays a crucial role in day-to-day operations.

3. Core Components of a Business Inventory Program

A modern inventory program typically consists of the following components:

A. Inventory Tracking

Tracks the movement and quantity of stock items in real-time across different locations.

B. Barcode and RFID Scanning

Facilitates fast and accurate tracking using barcode labels or RFID tags.

C. Order Management

Integrates purchasing and sales orders, ensuring accurate order processing.

D. Reporting and Analytics

Generates customizable reports on inventory turnover, reorder levels, and product performance.

E. Supplier and Vendor Management

Helps manage relationships and transactions with suppliers.

F. Demand Forecasting

Uses historical data and algorithms to predict future inventory needs.

G. Warehouse Management

Organizes stock locations, bin numbers, and warehouse workflows.

4. Types of Business Inventory Programs

Depending on the scale and nature of a business, there are various types of inventory programs:

A. Spreadsheets and Manual Systems

Used by small businesses; low-cost but prone to human error and inefficiency.

B. On-Premise Inventory Software

Installed locally on a company’s server, offering robust features but with higher upfront costs.

C. Cloud-Based Inventory Software

Accessible from anywhere, offers scalability, lower upfront costs, and automatic updates.

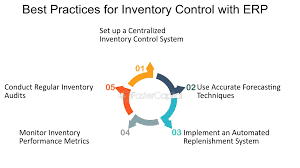

D. Enterprise Resource Planning (ERP) Systems

Integrated with other business functions (finance, HR, CRM); suitable for large enterprises.

E. Open-Source Inventory Software

Customizable and budget-friendly for companies with tech resources.

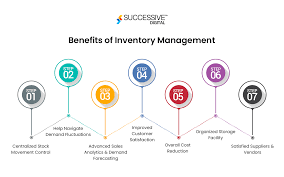

5. Benefits of Using a Business Inventory Program

Implementing an inventory program can transform the way a business operates:

A. Real-Time Visibility

Business owners and managers gain real-time insights into inventory status, reducing uncertainty.

B. Cost Reduction

Minimizes excess inventory, lowers holding costs, and avoids emergency restocking.

C. Better Customer Service

Ensures faster fulfillment, fewer backorders, and accurate delivery timelines.

D. Streamlined Operations

Automates repetitive tasks like reordering and inventory counts, improving productivity.

E. Data-Driven Decisions

Leverages analytics to identify trends, fast-moving products, and seasonal demand shifts.

F. Multi-Location Management

Ideal for businesses operating across various warehouses or retail outlets.

6. Choosing the Right Inventory Program

When selecting the ideal inventory solution, consider the following factors:

A. Business Size and Complexity

Startups may need basic tracking, while large retailers require advanced features.

B. Integration Needs

Ensure compatibility with existing tools like POS systems, accounting software, or ERP platforms.

C. Scalability

Choose a solution that can grow as your business expands.

D. User Interface

A simple and intuitive interface reduces the learning curve for staff.

E. Budget

Evaluate both upfront and recurring costs (licenses, support, updates).

F. Customization

Some businesses need industry-specific features, like lot tracking or expiration management.

7. Steps to Implement a Business Inventory Program

Proper implementation is key to realizing the full benefits of an inventory system:

Step 1: Assess Current Inventory Process

Document existing workflows, challenges, and objectives.

Step 2: Select the Right Software

Compare features, pricing, and user reviews. Request demos or trials.

Step 3: Clean Up Inventory Data

Before migration, remove outdated, duplicate, or incorrect records.

Step 4: Train Employees

Provide adequate training on how to use the new system effectively.

Step 5: Integrate with Existing Systems

Ensure seamless data exchange between inventory, sales, accounting, and e-commerce platforms.

Step 6: Test the System

Run a pilot program to catch potential bugs or user issues.

Step 7: Go Live and Monitor Performance

Monitor KPIs like stock turnover ratio, order accuracy, and fulfillment speed.

8. Challenges in Inventory Management

Despite having an advanced system, businesses may face inventory challenges such as:

A. Inaccurate Forecasting

Misjudging demand can lead to overstock or stockouts.

B. Inventory Shrinkage

Losses due to theft, damage, or misplacement.

C. Lack of Standardization

Disorganized processes across departments or locations.

D. Supplier Delays

Interruptions in the supply chain can disrupt inventory levels.

E. User Resistance

Employees may resist change due to fear of complexity or job impact.

Solutions:

-

Use predictive analytics

-

Conduct regular audits

-

Set clear SOPs

-

Maintain strong supplier communication

-

Offer change management training

9. Industry Use Cases

Retail Industry

Manages thousands of SKUs across multiple stores and warehouses. Needs real-time stock updates, auto-reordering, and seamless POS integration.

E-Commerce Businesses

Require integration with online platforms like Shopify or WooCommerce, and features like dropshipping and shipping label generation.

Manufacturing Companies

Need raw material tracking, bill of materials (BOM) management, and work-in-progress (WIP) monitoring.

Healthcare and Pharmaceuticals

Focus on lot tracking, expiration dates, and compliance with regulations (FDA, HIPAA).

Food and Beverage

Must manage perishable inventory, FIFO (First-In, First-Out) systems, and seasonal demand.

10. Best Business Inventory Programs in 2025

Here are some leading inventory software solutions:

1. NetSuite ERP

Comprehensive ERP with strong inventory, finance, and CRM integration.

2. TradeGecko (Now QuickBooks Commerce)

User-friendly interface with solid e-commerce integrations.

3. Zoho Inventory

Affordable cloud-based platform for small to mid-sized businesses.

4. Fishbowl Inventory

Popular among manufacturers and warehouses, integrates with QuickBooks.

5. Cin7

Good for retail and B2B, with built-in POS and warehouse tools.

6. inFlow Inventory

Simple solution for small businesses; supports barcoding and invoicing.

11. Future Trends in Inventory Management

As technology evolves, so does inventory control. Expect to see:

A. Artificial Intelligence (AI)

AI-driven forecasting, demand sensing, and inventory optimization.

B. Internet of Things (IoT)

Smart sensors in warehouses to track real-time stock movement.

C. Blockchain

Enhanced traceability and transparency across the supply chain.

D. Mobile Apps

Mobile-first platforms for inventory tracking on the go.

E. Drones and Robotics

Automation of warehouse operations and real-time scanning.

12. Conclusion

A business inventory program is more than a digital ledger—it’s a strategic asset that drives operational excellence, customer satisfaction, and profitability. Whether you’re a small e-commerce brand or a multinational manufacturer, the right inventory system can streamline your processes, reduce costs, and position your business for growth.

Investing in a modern inventory solution is not just a technological upgrade; it’s a business necessity. With thoughtful planning, the right tools, and a commitment to continuous improvement, your organization can master inventory management and unlock long-term success.